medical bandage

The bandage produced by TEDA covers the entire bandage product, including plaster of Paris bandage, crepe bandage, orthopedic casting tape

The Manufacturing Process Of Medical Bandage

The raw material

Weaving

Disinfection

Cutting and packing

catalogue

The production process

We produce a lot of different kinds of medical bandages, and they all have different uses, but the production process is pretty much the same except for the materials and the weaving process.

Raw material

Weaving

Disinfection

Cutting

Packing

raw material

All the traditional medical bandages of Tedamed are made of pure cotton, matt or light viscose rayon. Viscose rayon is the best raw material for traditional medical bandages because it does not need bleaching and has the lowest cost. Pure cotton is the most used because it is not to cause allergic symptoms.

Tedamed’s traditional medical bandages are: Tubalar Bandage, Gauze Bandage.

The main raw materials of Tedamed medical elastic bandage are non-woven, cotton, spandex, Polyester, rubber, Velvet, nylon.

different kinds of raw materials and different kinds of weaving methods, making each kind of medical elastic bandage has its own characteristics.

Tedamed’s medical elastic bandages include: Net Tubalar Bandage, Elastic Crepe Bandage ,Elastic Bandage ,Crepe Bandage With Red Blue Line,Cohesive Bandage,PBT bandage,skin traction kit.

The raw materials for Tedamed’s orthopedic medical bandages include Cotton, Fiberglass, and Gypsum Plaster. Their main function is to stabilize the injured area until recovery after curing.

Tedamed’s Orthopedic Bandage are: Orthopedic Casting Tape, Orthopedic Cast Padding, Plaster Of Paris Bandage.

weaving

In the weaving process, the raw materials need to be beam-warping first and then woven. Orthopedic bandages also need to complete the spraying of coatings.

beam-warping

The purpose of warping is to wind the bobble yarn to the warp axis at the same tension in parallel and equal speed, orderly and neatly arranged according to the number and length of warp yarn required by the process, the order and density.

(1)In the warping process, the tension of each warp must be uniform and constant as far as possible in each winding process, and the tension value is not Can be too large or too small, different materials of yarn warping tension size should also be different;

(2) The warp shaft is well formed, the surface is smooth, and the warp yarn level is clear. Ensure smooth unwinding;

(3) the warp yarn is evenly distributed horizontally, neatly arranged and with appropriate density;

(4) The number and length of warp threads on the warp shaft should meet the technological requirements. On the same warp axis, the winding number of each coiling yarn should be the same and the length should be the same.

(5) During warping, lubricants can be added to improve the weaving performance. Make it smooth and soft;

(6) The temperature and humidity of the warping workshop should be appropriate, which has a significant impact on the warping quality. The general control temperature is 25±5℃, relatively wet Degree: 65± 5%. At the same time, the temperature and humidity to keep stable, can not have a sharp change.

weaving

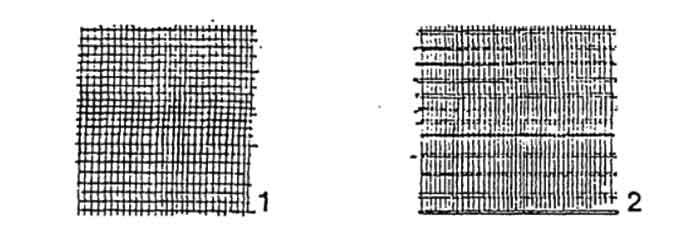

We use the double needle bed warp knitting machine to complete most of the medical bandage weaving. We use the process of threading yarn to yarn and cushion yarn to complete the weaving. Six comb bars are woven.Below is the warp and weft diagram of the bandages we weave,

There are also requirements for spraying objects, so the raw material of orthopedic casting tape is glass fiber. Glass fiber is an inorganic nonmetallic material when it is drawn Micrometer-grade fibers not only retain the excellent physical and chemical properties of glass Yes, and there are some new features and “performance setables. Calculation and processing “, which is incomparable to other traditional materials. So with glass fiber as the base material, with other performance is more excellent Machine or inorganic new materials for coating composite materials, not only glass The performance of the fiber is further improved, while the special coating material The composite material can be properly treated to obtain the desired Technical application performance.

Glass fiber yarn is a kind of brittle yarn, usually not Suitable for knitting. The properties of fiberglass yarn should conform to the knitting process Production requirements, must take the following measures: reduce glass fiber single fiber The diameter of a glass fiber or coated with a layer to soften it Infiltration agent. The former will greatly increase the cost; The latter uses the combination Suitable special wetting agent to make glass fiber can be knitted is the most tangible benefits.

spraying

The spraying process is mainly applied to the processing of orthopedic casting tape. In order to improve the interfacial bond between glass fiber and polymer, Often in the glass fiber surface coated with the corresponding trace coupling agent, the The mechanism is chemical bonding. One end of the coupling agent can be connected to the glass fiber surface The surface is covalently bonded with Si -OH group and the other end is physicalized with polymerization So the glass fiber and polymer can get the strongest Interface bonding. This is useful for improving glass fiber composites in machinery Performance, electrical insulation, water resistance, aging resistance and life extension Etc have significant effects.

Glass fiber surface coated with wetting agent, will be coated after the glass The adhesive property of polyurethane resin of glass fiber tape has some bad effects Ring. Unsuitable components can be removed by post-treatment and coated On the appropriate coupling agent, so that the glass fiber and polyurethane resin adhesion And improve.

Disinfection

Disinfection is defined in the Technical Specifications for Disinfection as the killing or elimination of vectors Introduce pathogenic microorganism, make it reach harmless treatment. At present, the more mature disinfection method has physical disinfection method and chemical disinfection method. Physical disinfection Methods include: natural purification, mechanical force removal, thermal disinfection, radiation disinfection and microwave disinfection; Chemical disinfection method includes: spray or wipe, aqueous solution sink bubble And fumigate with gas. Due to the structure and use characteristics of the product, the disinfection method is high-temperature cooking, drying, ultraviolet disinfection or ethylene oxide disinfection.

(1) Cooking, washing and drying. Use physical and chemical methods to reduce the organic matter, inorganic matter and microorganisms attached to the fabric to a relatively safe Levels. First, add chemical additives in 100℃ high temperature cooking 1h, remove impurities, oil, dust, etc., followed by rinsing, neutralization and after Continuous drying finishing, commonly used is automatic or semi-automatic washing machine, good conditions can use standard washing machine to more accurate control washing process. The water temperature Cannot exceed 40℃.

(2) Ultraviolet disinfection. It has the advantages of safety, convenient operation, economy, no harmful substance residue and less damage to articles. It can be killed in a few seconds All kinds of microbes. But ultraviolet rays can hurt your eyes, so take protective measures. The ultraviolet wavelength used for disinfection is 253.7 nm.

(3) ethylene oxide gas sterilization. Ethylene oxide has strong killing ability to microorganisms, non-corrosive to the object of sterilization, small damage, sterilization effect Good, high reliability, but certain toxicity, flammable, explosive, easy to residue and long operation time, about 6 hours

cutting and packing

After disinfection, the product is cut off in accordance with the required length, and finally packed with balers.

Our main bandages are 3.6m*5cm, 4m*7.5cm, 4.5m*10cm and so on.

We use aluminum fasteners to fix most of the bandages

Specific can also be customized according to your needs.

Mr.Terry

General manager of suzhou tedamed Co.,ltd

Mob/whatsapp :

+8618814865424

+8618012759580

ADD:Room 317-318,938 Gaoxin Road , Wujiang district , Suzhou,Jiangsu,China

Email: tedamed@126.com chinadamed@gmail.com